The sandwich panel has revolutionized the architecture and construction sector. In this sense, the construction industry has experienced a significant transformation in the last decade, driven by the search for more efficient, sustainable solutions and lower costs.

The incorporation of sandwich panels in construction projects with marble and ceramics represents an evolution in the construction industry. These panels offer a versatile, functional and effective solution that allows you to speed up building and cladding work, while maintaining the aesthetics and durability that characterize these materials.

Given its robustness and structural rigidity, weight reduction and aesthetic appeal, the use of sandwich panels has become popular throughout the world. Thus, large manufacturers and distributors of ceramic and natural stone construction materials have added sandwich panels to their product portfolio.

Among the main applications of sandwich panels are façade cladding, as well as the creation of walls, floors and ceilings and the installation of prefabricated houses. It is a very versatile material available in a wide variety of dimensions and designs and offers great durability against environmental damages, with a long useful life and reduced maintenance.

This innovative solution allows to reduce the material’s weight to lighten the constructions, which facilitates both transportation and installation. Likewise, given their composition, sandwich panels offer optimal insulation, which improves the energy efficiency of buildings.

Problems in ceramic and natural stone sandwich panel manufacturing

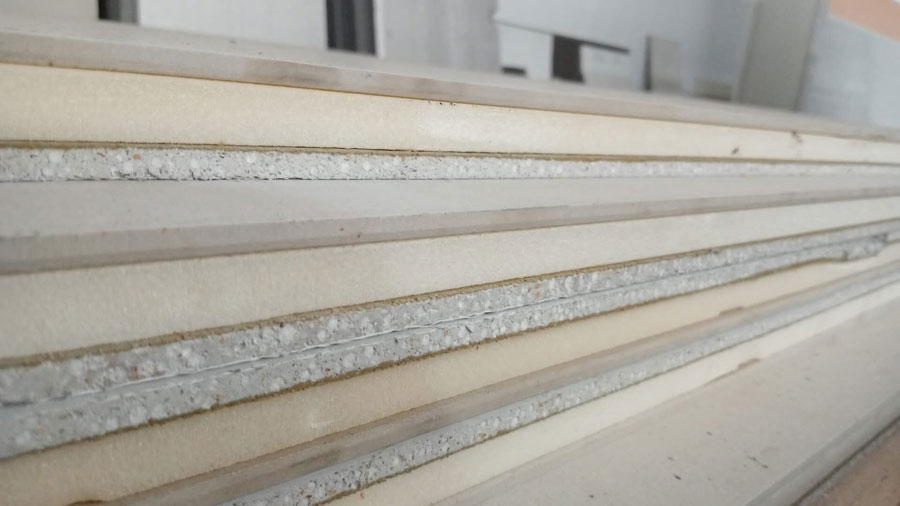

The marble and ceramics industry face a great production challenge for sandwich panels. These panels are composed of three layers: two outer layers made of stone or ceramic and the inner core composed of insulating material to offer structural rigidity with low weight.

The main problems faced by manufacturers of ceramic and natural stone sandwich panels are listed below:

- Breakage of the stone/ceramic surface during the manufacturing process.

- Deficient adhesion of the layers.

- Weakness of the final piece.

- Poor aesthetic finish.

The solution to breaks and manufacturing defects of ceramic and natural stone sandwich panel

The Xilex for Stone drying and resining inline solution has been implemented by some of the main sandwich panel manufacturers. Xilex for Stone technology carries out an optimal drying, resin filtration and mesh adhesion process that results in the manufacturing of a high quality, robust and durable product. Likewise, the process efficiency of the Xilex lines translates into a reduction of up to 20% in production costs based on energy and resins savings, as well as minimization of material breaks and processing time.

Contact us to receive information on the application of Xilex for Stone technological solutions for the manufacture of sandwich panels and ceramic and natural stone slabs.

Recent Comments