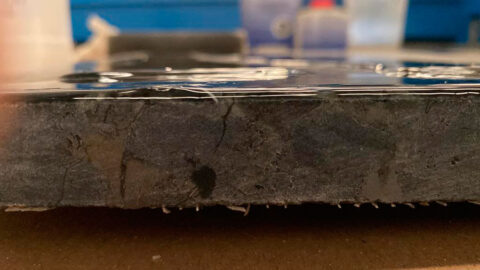

Resin filtration control and mesh adhesion are critical within the natural stone slabs production process. These steps directly revert the quality, robustness and aesthetic final result of the slabs.

Natural stone slabs manufacturers face serious production problems due to the breakage and finishing defects, which are mainly related to faulty resin filtration and mesh adhesion treatments. These defects represent a huge burden for the companies as they have to discard the materials or repeat the treatments. Thus, production costs are heavily increased due to the process’s repetition (energy consumption, resources and time) and material waste.

Timeless beauty and durability of the natural stone slabs make this material the preferred choice for architectural and interior design projects. However, working with materials like marble and granite requires specific innovative technology which can solve the harsh production problems that the industry has been dragging for decades.

Natural stone slabs production weak factors

Natural stone slabs are prone to breakage and defects during the polishing process due to their inherent composition and structure. To overcome these challenges, it is crucial to comprehend the factors that contribute to these issues.

- Material composition. Natural stones have diverse unique mineral compositions. Variations in hardness and grain structure influence how these stones respond to the slab’s

- Improper processing. Inadequate handling, such as defective drying, resin filtration or defective mesh adhesion, can lead to cracks and breakage in the delicate stone surface.

- Inadequate equipment. Outdated or improper equipment can cause inconsistencies resulting in breakages and defects on the stone surface (stains, hay marks, spots…).

Resin filtration control as the key of the natural stone slabs quality

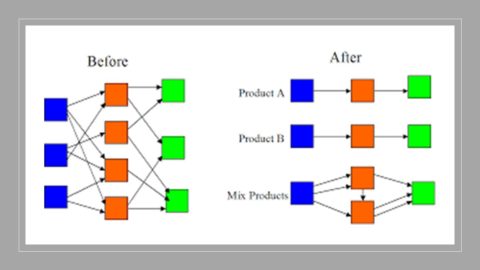

Xilex for Stone tackles this challenge by providing an effective, efficient and easy-to-adapt solution. Xilex for Stone drying and resin application equipment enhance the quality of natural stone slabs by performing an excellent fast drying and a precise control of the resin filtration.

By meticulously managing resin filtration through specialized recipes, noticeable process improvements are observed after the slab polishing stage. Natural stone slabs processed using Xilex for Stone machinery exhibit a superior consolidation, facilitating the polishing process and minimizing the risk of breakages afterwards.

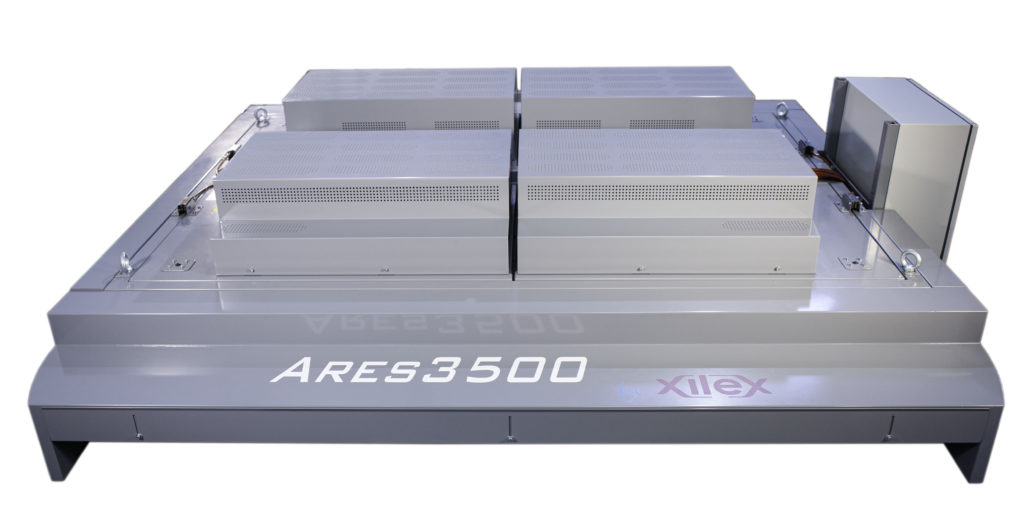

Xilex for Stone drying and resin control solutions

Xilex for Stone Ares drying and Kronos resining machines, excel in the natural stone production lines. The effective fast drying and optimum resin filtration control boost productivity up to 30%. Our machines ensure slabs are ready for polishing within just 1 hour, avoiding waiting times of 24h-48h-72h, so driving out the intermediate storage spaces. This successful inline treatment ensures a seamless production process.

Furthermore, the efficiency leads to a cut down of the costs up to 20% related to lower power consumption, minimization of resins usage, material waste reduction and time optimization

Contact us to book a consultation session, Xilex for Stone technical experts will advise you on how to solve breakages and quality defaults on natural stone slabs.

Recent Comments