Time is a fundamental value in all companies and also in natural stone manufacturers, marble and granite. For this reason, Xilex has developed Ares and Kronos ovens: a solution that allows to work in continuous to have slabs finished in 5 hours.

Transforming a conventional line to carrying out continuous work is possible with the simple adaptation of the line with Xilex machinery. With Ares and Kronos, which are installed quickly and easily, waiting times 24h-48h-72h are permanently eliminated, and slabs can be finished with the polishing process in one day.

Advantages of continuous work with Ares and Kronos.

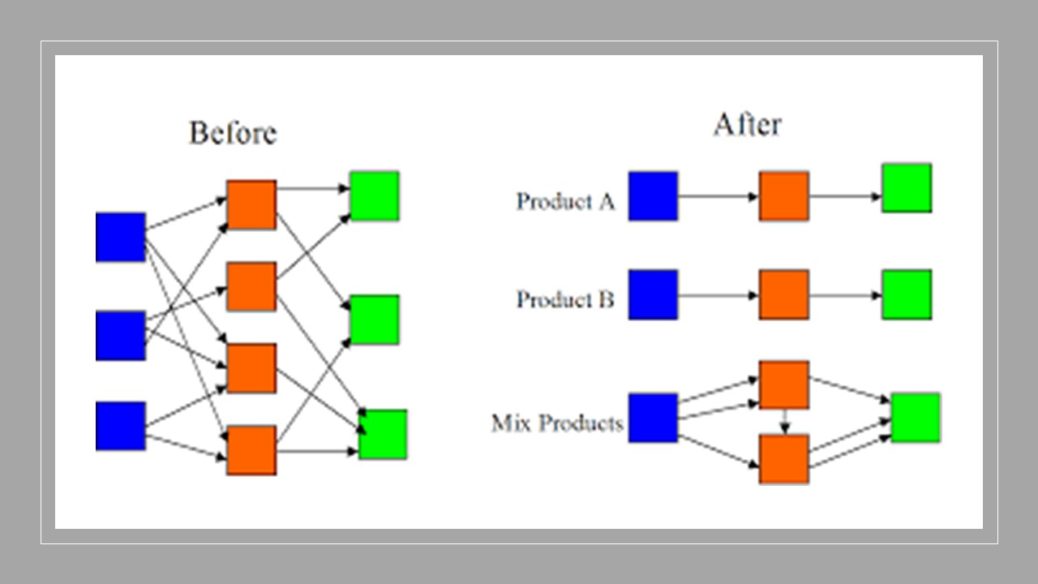

In conventional plants, the treatment of the slabs is carried out by phases, which increases the production cost in relation to the waiting times and the handling of materials: loading-unloading, intermediate warehouses, breaks due to manipulation …

With Ares and Kronos ovens from Xilex, old conventional lines acquire the functionality of a continuous working line and intermediate warehouses and waiting times disappear. Thus, with Xilex machines, production can complete all its phases from primary blocks to polishing in a total time of 5 hours.

Savings and 30% increase in productivity.

In this way, due to Kronos and Ares, companies productivity increases 30%, which translates into a significant increase in profits. For example, companies in marble and granite sector that work with Xilex machines and have a production of 100,000 slabs per year, achieve approximately a saving of € 350,000.

It is important to highlight that this saving is related to work in continuous and by the reduction in energy costs and resin consumption due to Xilex machinery. To this savings must also be added the recovery of waste materials, which is around 6%.

[/vc_column_text][/vc_column][/vc_row]

Recent Comments