Marble and granite market demands high-quality products at competitive prices. This is the main reason why natural stone slab manufacturers decide to upgrade production lines with Xilex solutions.

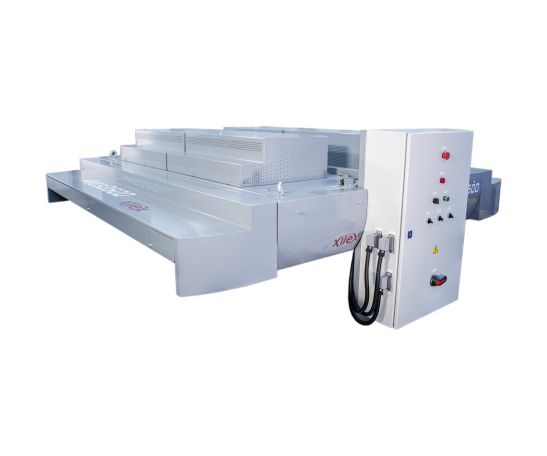

With a simple installation of the drying and resin ovens, Ares and Kronos, manufacturers manage to improve the quality of their products while reducing costs and increasing their productivity by up to 30%.

More than a dozen companies in the marble and granite sector in Spain, Italy and Brazil have already improved the quality of their products and processes with the installation of Ares and Kronos. These producers have managed to work “calmly” with materials that had many processing problems, which prevented them to be treated. With the Xilex system they can work with all kinds of materials optimally and quickly, avoiding breakages and obtaining superior qualities than those made by conventional ovens.

Advantages of Ares and Kronos for marble and granite manufacturers

Advantages of Ares and Kronos for marble and granite manufacturers

Xilex machines are easily installed and adapted to production lines, they are functional equipment designed to respond to producers who want to position themselves in the natural stone market as reference suppliers.

The advantage of working with Xilex machinery is based both on increasing the quality of the final product and on the savings it provides to companies:

Quality increase of marble and granite slabs:

- Better filtering of the resin without vacuum.

- Greater resistance: breakage reduction and longer gloss duration.

- Achievement of finishes and controlled effects (light and dark tones) and longer gloss.

Economic savings of up to 350,000€ per year on lines of 30 slabs / hour. These savings are mainly due to the following achievements:

- 30% productivity increase due to:

- online work and continuous manufacturing system. With Ares and Kronos from Xilex, the pieces are ready in just a few hours, as opposed to the 24h-48h-72h times of conventional lines

- minimization of board breaks and rework of materials.

- processing of very difficult boards, usually from the edges of the blocks, which, being resinized with our equipment, can be marketed, which is not possible with conventional ovens.

This can represent savings of up to 300,000€ / year

- Lower energy consumption, which translates into an saving of up to 30,000 euros per year.

- Lower resin consumption due to effective product filtration. This can represent savings of up to 20,000 euros/ year in chemical products.

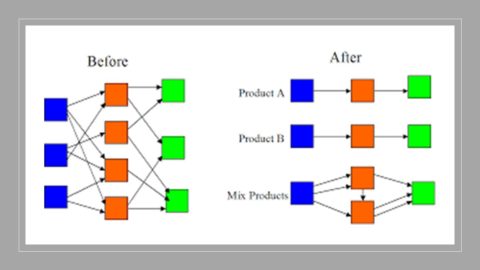

Adaptation of a conventional line with the Ares and Kronos ovens

The installation of both machines is done quickly and easily. Given their small dimensions and their agile adaptation to the pre-existing production line, they do not require masonary or foundation. Thus, for its installation it is only necessary to couple the machines to the production line and connect them to the electrical connection.

They are functional machines and very easy to handle, so they integrate perfectly into the way of working of the operators. Likewise, Xilex carries out practical training and provides advice for start-up, as well as providing resources and recipes with which to optimize the use of resins with the new machines.

Once the installation has been carried out, Xilex has a maintenance service and customer service to offer the maximum guarantees of trust to the companies that work with its technology.

Recent Comments