Xilex, specialist in the development of machinery for the treatment of stone and granite, improves the drying and resin processes with Ares and Kronos.

Xilex has installed its Ares and Kronos machines in an important company in the natural stone sector in Novelda area (Alicante) to solve problems of filtering and adhesion of the mesh.

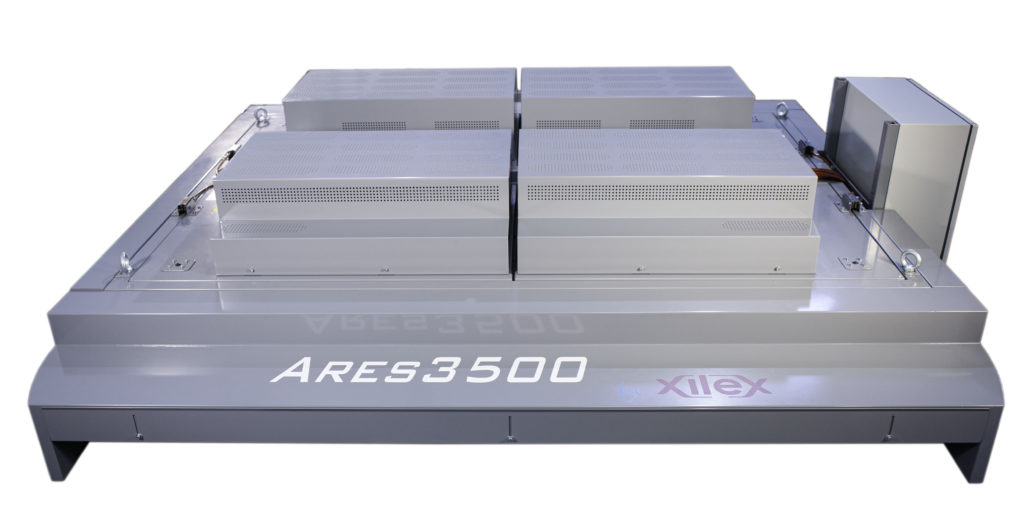

This company, dedicated to the manufacturing of slabs for third parties, has updated its production line by installing Ares 3500 and Kronos 3500 machines, with the aim of distinguishing itself among competitors in the sector as a leading supplier of high quality slabs with reduced times of delivery.

Maximum efficiency and control in filtering and adhesion in marble and granite

The final finishing is the decisive element of any company that works with marble and granite, and reducing the treatment time is an important added value. This company, in addition to working with conventional marble and granite, develops works with exotic granite, which presents greater difficulty in treatment.

With the installation of Xilex machines in their conventional line, they have managed to effectively control the filtration of the resin in hairs and cracks, so that the operator can adjust it precisely according to the type of marble or granite, or in relation to the type of reinforcement or finish. Also, Kronos and Ares solve successfully the technical problems of adhesion of the mesh and breakage of slabs with an optimal drying process.

For the execution of these processes with Xilex machines, Tenax resins have been used, a trusted brand that allows product modifications based on the needs of the materials to achieve the desired finish on the slabs.

Treatment time reduction: produces up to 15 more slabs every hour

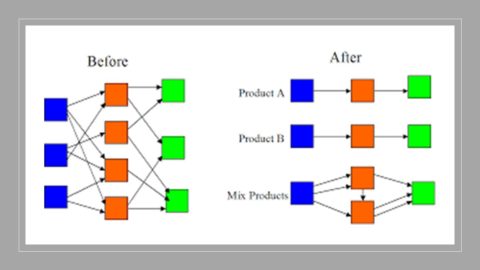

The work of Xilex machines in a conventional line allows to increase productivity by more than 25%. In that company in Novelda, its line treated only 15 tables / hour, and now with Kronos and Ares they process 25/30 slabs per hour, depending on the type of material. This exponential increase in efficiency is based on the exclusive drying and resin systems incorporated by the Ares and Kronos machines, which do not require greater energy expenditure.

Fast adaptation in a conventional line with Xilex machinery

The renewal of the production line of this Novelda company has consisted of a simple adaptation in the resin process for polyester and epoxy. For this, only two machines have been installed, designed and manufactured by Xilex in Spain. These machines for marble and granite are Ares 3500 for moisture drying and Kronos 3500 for proper filtration and hardening of the resin. These are small-sized machines (2.5m and 3.5m respectively), whose assembly and start up only requires four days, both adapting to the standard size of the transport tables.

Recent Comments